With much of rural India still affected by COVID-19, AMMACHI Labs formulated an innovative online training program. The tailoring initiative supports skill development for village women in the field of sustainable fashion.

Named Vastra Chakra, a Sanskrit term which literally translates to clothing wheel, the initiative carries the overall goal of empowering rural women through upcycling used clothing into products of a higher value. The project uses the Internet as the means to reach women in remote areas. Phase one took place in villages in North India.

Sustainable fashion refers to clothing that is designed, manufactured, distributed, and used in ways that are environmentally friendly. The fast fashion cycle is far from sustainable, because it depletes the Earth’s natural resources at exponential rates, exploits workers around the world, and results in an overwhelming amount of waste.

Clothing and textile is a $2.4 trillion-dollar global entity that employs approximately 300 million people across the value chain, many of whom are women, and the scale of the industry is only expected to grow over the coming years.

But alongside, there are currently serious unsustainable practices that include social and environmental consequences. The United Nations Environment Programme states that without major change to production processes and consumption patterns in fashion, the social and environmental costs of the sector will continue to mount.

Facts include:

- Fashion is responsible for an estimated 2-8% of the world’s greenhouse gas emissions.

- Around 215 trillion liters of water per year are consumed by the industry.

- Textiles account for approximately 9% of annual microplastic losses to the oceans.

Upcycling is a process that is accessible for both small and large scale production. It is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products perceived to be of greater quality, such as artistic value or environmental value.

Based on these concepts, the Vastra Chakra program focuses on creating awareness about textile waste management as a step in the conservation of nature. Alongside, it seeks to instill creativity in the village women by providing them with ideas to reuse things like their old saris, shirts, pants, and jeans into new clothing items or home textile products.

In phase one of the project, the product developed is of essential use during the pandemic. Women recut and reused whatever old material they had on hand to make a COVID-19 facemask that is attached via ear muffs. In the big picture, it gives them a new way to express themselves with a vision for the good of the world.

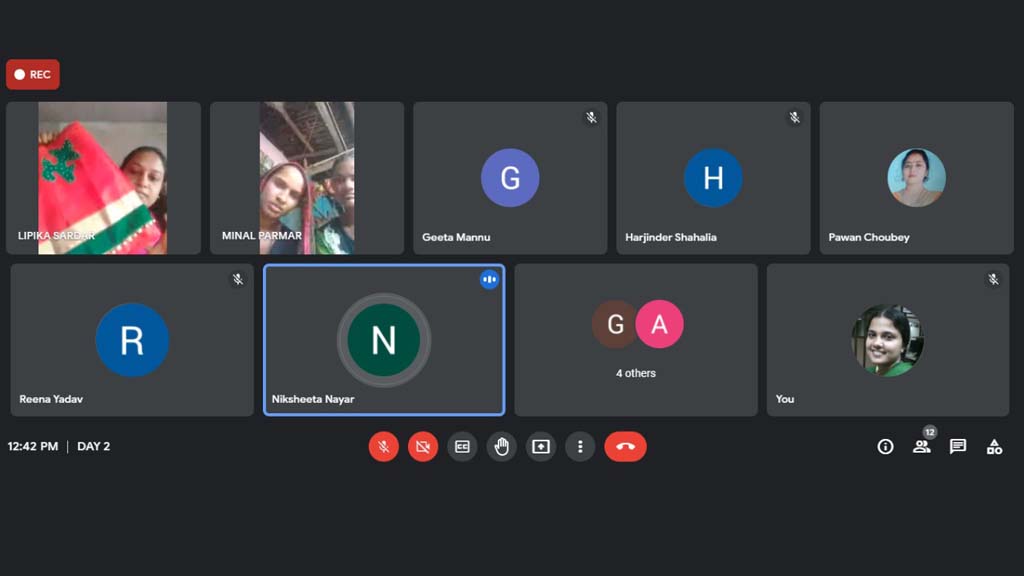

The majority of the women who took part were previously trained through AMMACHI Labs tailoring programs. Due to COVID-19 challenges, Vastra Chakra was designed to be delivered completely online. This gives the women the added benefit to enhance their capacity to operate and learn through digital technology.

The first level of the online training program was successfully completed in villages in Bihar, Madhya Pradesh, Uttarakhand, Gujarat, Uttar Pradesh, Himachal Pradesh, West Bengal and Punjab.

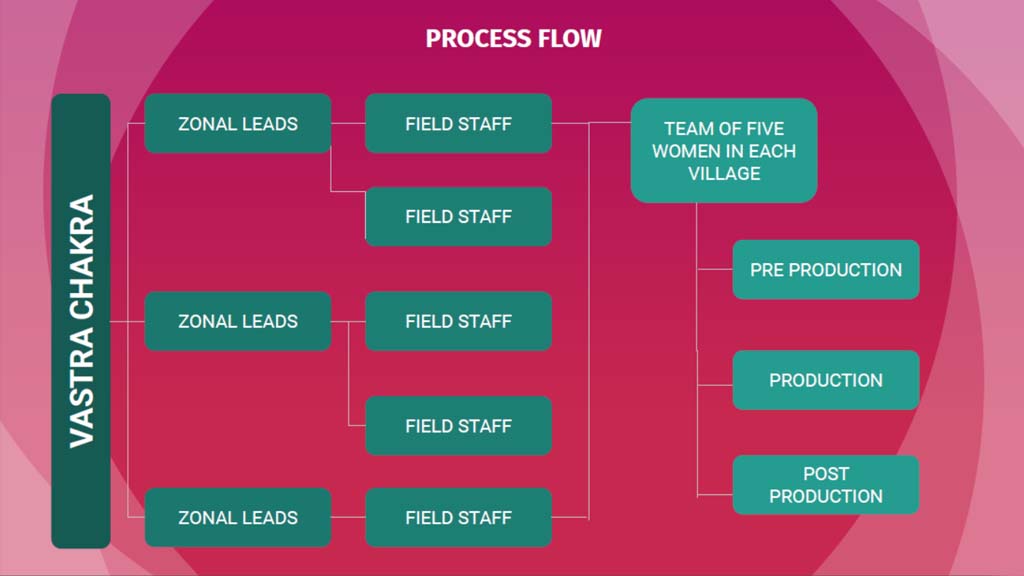

Along with AMMACHI Labs zonal leads and field staff, a team of women from each village was formed to lead the project. This maintains a cooperative approach that transfers the skills to the villagers so they have a foundation upon which to build their futures. The process is built upon a clear network.

The overall vision takes a collective approach and seeks to include people in the village who cannot support themselves. For example with facemask production, teams made sure to make a list of names of all women and how they could take part or be supported. In this case, especially women above the age of 70 who are poor.

Step 1: Pre-Production

Collection of Raw Materials – The raw materials can be collected from the neighboring houses or tailoring shops in the village. Sort it out based on colors.

Online Training – Online training sessions on production are given and a sample product is made.

Step 2: Production

Processing – All the materials used are washed and ironed.

Pattern Making – The measurements of the product are given and the women create a pattern and cut the fabric.

Construction – Based on the cutting, the tailoring women start sewing. Teams brainstorm decoration ideas.

Step 3: Post Production

Quality Check – The quality of the product is checked to see if any corrections need to be made.